DWL-5000XY Series Control Box

The Control Box enables single or multiple Digi-Pas® 2-Axis inclination sensor modules to be accessed in real-time through various industrial communication protocols such as USB, RS232, RS485 & Wireless Bluetooth. It is the hardware specifically developed to empower Application Engineers to instantly (i.e. plug & play) gaining access to leveling and angular readings without the need for writing those time consuming software codes.

Specification

| Programmable Relay Contacts Outputs | 4 x SPDT Relay – 3A at 30 VDC (NC), 5A at 30 VDC (NO) |

| I/O communication protocols | RS232/ RS485: 8 Data bits, no parity, 1 stop bits, 115200bps |

| USB: 2.0 | |

| Bluetooth: Industrial Class 1 (optional) | |

| Power supply | 12V DC |

| Max. current consumption | 1.2 A |

| RS485 interface for Digi-Pas® 2-Axis sensor modules | |

| Operating temperature | -20°C to +70°C |

| Storage temperature | -30°C to +80°C |

| Weight | Approx. 490g |

| Dimension | 234 x 132 x 53 mm |

Benefit

The Control Box is a "Development Kit" (when used in conjunction with PC Sync Software - Pro edition) is particularly useful to INSTANTLY and EFFECTIVELY allows application engineers/scientist to extract leveling and angular readings in real-time from a single/multiple inclination sensor(s) without the need for concerning on the lead times for writting own programming codes, during preliminary assessment on a project.

Its relay outputs provide application engineers immediate flexibility to set targeted tilt angle/vibration values via the Professional PC Sync software to initiate trigger/control on external peripheral devices such as siren/alarm, valve, motor, strobe lights, etc.

Able to operate independently to trigger relay contacts after PC is detached from the Control Box

Allows up to 4 of sensor modules connection simultaneously for real-time monitoring (note: system response time increases progressively with number of sensor added)

LED indications for active sensor module connected

Multiple I/O communication protocols such as USB, RS232, RS485 & Wireless Bluetooth, available to meet requirement of various applications

Download

Application diagram

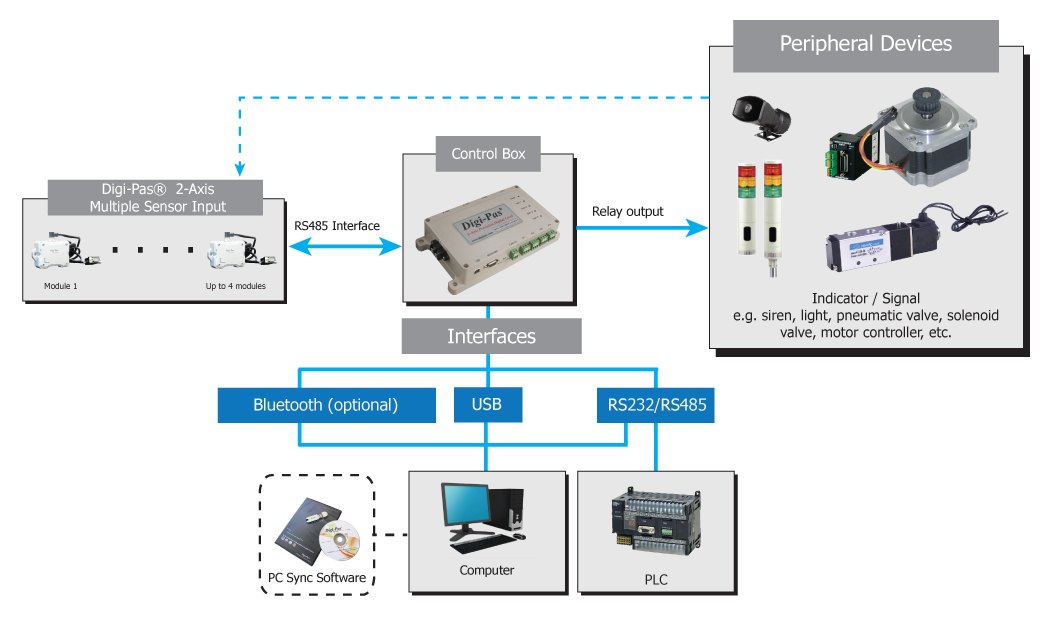

Application diagram 1 - Multiple Sensor Modules

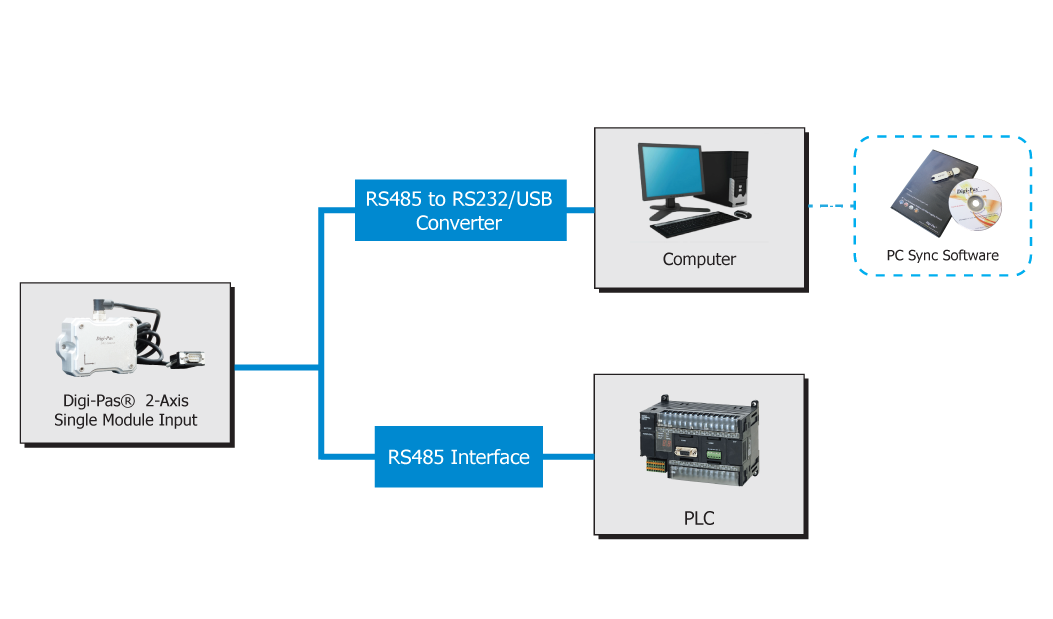

Application diagram 2 - Single Sensor Module

Features

-

MULTIPLE I/O PROTOCOLS

Various standard industrial communication protocols available i.e. USB 2.0, RS232 & RS485

-

RELAY CONTACT OUTPUT

Enable user to configure relay output setting to trigger external peripheral device. (e.g. siren, valve, strobe light, motor, etc.)

-

USB LINK TO PC

USB connection for remote acquisition, monitoring, data logging & analysis in computer.

-

PC SYNC SOFTWARE - BASIC EDITION

Enable basic features of remote data acquisition on Angular Measurements.

-

WIRELESS SYNC (OPTIONAL)

Wireless connection (Bluetooth industrial class 1) for remote monitoring, data logging & analysis from computer. (PRO PC sync software is required)

-

PC SYNC SOFTWARE - PROFESSIONAL EDITION (OPTIONAL)

Enable advance features to set parameters and triggering relay outputs for remote data acquisition, logging, processing, analysis on angular measurements and control output of peripheral devices.