2-Achsen-Vertikalpräzisions-Digitalwaage – Model: DWL-1900XY

- Measuring Range: 90.000° ~ ±5.000° dual-axis

-

Measurement Resolution Table:

Vertical Stroke Length (mm) Resolution 50 1µm / 50mm 100 2µm / 100mm 150 3µm / 150mm 300 5µm / 300mm 400 7µm / 400mm 500 9µm / 500mm 800 14µm / 800mm 1,000 17µm / 1,000mm - Measurement Accuracy: Zy-axis: ± 34µm/1,000mm stroke length at (90.000°±0.500°) ± 68µm/1,000mm stroke length at other angles

Zx-axis: ± 34µm/1,000mm stroke length at (90.000°±0.500°) ± 68µm/1,000mm at other angles - Operating Temperature: 10°F to 120°F or -10°C to +50°C

- User may use device without or with Bluetooth® Measurement when paired with smartphone & Digi-Pas Smart level App (Optional)(Bluetooth range: approx. 15mtr)

- ACCURACY of Digi-Pas digital level is verified by accredited 3rd Party Calibration & Test Laboratories in USA, Japan and Germany traceable to NIST, JIS & DIN.

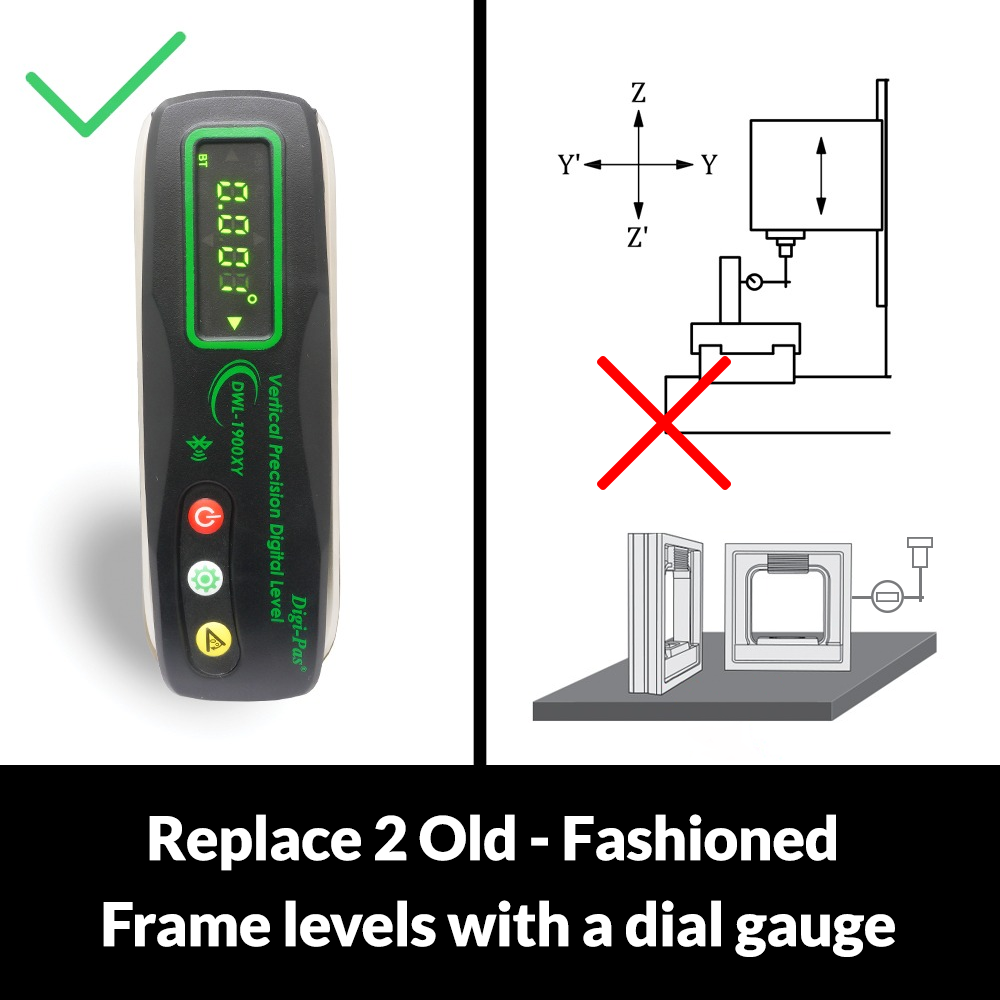

Precision angular measurement/alignment on vertical axis essentially involves two intertwined vertical planes (2-axis i.e. Zx & Zy) which demand for 2-dimensional solution rather than the outdated single-axis method using Frame/Rectangular spirit vial level that could only indicates 'one axis at a time'. But, in reality, aligning one vertical axis of a plane (such as a vertical spindle shaft. e.g. Zx axis) would simultaneously change the angle on the other plane of the shaft e.g Zy axis.

Digi-Pas DWL1900XY provides measuring readings on both Zx & Zy axis simultaneously in great precision and when combined with the use of DWL1500XY on horizontal Hx & Hy axis at surface of machine work-table leveling planes, they simultaneously display measuring readings on the PERPENDICULARITY of VERTICAL against HORIZONTAL Planes.

Digi-Pas DWL-1900XY is an AFFORDABLE Wireless-Bluetooth, Dual-Axis VERTICAL Precision Digital Level designed for industrial users & professionals. DWL-1900XY replaces old-fashioned FRAME vial levels. Users read both VERTICAL Zx & Zy axis plane angular readings wirelessly via Bluetooth, which effectively cuts down installation & setup ALIGNMENT time effortlessly for precision CNC machines & Coordinate Measurement equipment, especially when used in conjunction with "DigiPas Smart Level" Mobile App (Free one redeemable app with each purchase) with user’s smartphone (additional option to purchase multiple app available on Apple & Android App Stores).

Digi-Pas Precision Digital Level is highly accurate, verified by 3rd parties accredited calibration labs & test bodies in US, Japan & Germany in accordance with ISO/IEC 17025:2005 and ANSI/NCSL Z540-1 standard, traceable to NIST, JIS & DIN. "

Features

-

MODE

Switch angle display between X & Y Axis

-

ALTERNATE ZERO SETTING

Enable user to measure relative angles at a common plane with respect to a reference angle. The reference angle can be set using alternate zero feature.

-

ABSOLUTE LEVEL SETTING

Enables user to perform absolute symmetry readings for both "front" & "reverse" (180 degrees) positions of any measurement angle.

-

USER SELF CALIBRATION

Easy self-calibration feature allows user to reset the digital level back to factory preset accuracy.

-

"Digi-Pas Mechinist Level" APP (SMARTPHONE/TABLET)

Users may fully utilize Bluetooth mobile features for wireless levelling/alignment activities. One App is FREE to be redeemed for each purchase. Additional PAID Apps can be purchased from Apple and Google Stores. Each App works with the designated smartphone/tablet. Each App can connect with any device DWL1900XY (no restriction).

Download

Mobile application download

Steps to Redeem your 1st FREE "Smart Level App"

First, please download Smart Level Sync App from Apple or Google Store into your smartphone or tablet to enable FREE redemption of your app. If you who need more than one app to share a single device among multiple users, additional paid-apps can be purchased from Apple or Google Store.

NEXT, please follow steps below:

Step 1

Tap "Redeem" on top right corner of App.

Step 2

Gently scratch off the label on the back of the App Card accompanied to reveal the hidden 16-digit code.

Step 3

Enter the 16-digit code & Company name then tap "Redeem" button.

Step 4

"Redemption Successful" is prompted and you can use full features of the App now.

Mobile Application Key Features

| FREE | PRO | ||

|---|---|---|---|

| FEATURES | |||

|

Calibration | ||

|

Single Axis | ||

|

Smart 2D Bubble® | ||

|

Quick Snap | ||

|

Multiple Device | ||

| FUNCTIONS | |||

|

Absolute level | ||

|

Alternate Zero | ||

|

Units Measurement Change | ||

|

Enlarge | ||

|

Hold | ||

Applications

Digi-Pas® DWL-1900XY VERTICAL Level is used in conjunction with DWL1500XY HORIZONTAL Level as an EFFECTIVE & FAST ALIGNING and CHECKING method REPLACING the Old-fashioned way of using FRAME vial level with a Dial-Gauge on inspection for CNC machines and Coordinate Measurement equipment VERTICAL spindle shaft on:

- Straightness of Z-Axis motion,

- Squareness of the Z-axis motion to the Y-axis Motion,

- Parallelism of the spindle axis to the Z-axis motion,

- Squareness of the table surface to the Z-Axis motion

and other checking points in accordance to ISO 10791-2 & JIS B 6336-2 for Geometric test standards for CNC machines and Coordinate Measurement equipment comprising a vertical spindle shaft (vertical Z-axis) with respect to the surface plan of work-table.

-

Digi-Pas® 2-Axis precision VERTICAL digital level simultaneous display of two-dimension plane angles, effectively simplifying and resolving the hurdles of taking a vertical plane (Z-AXIS) angle 'one axis at a time' iteration (tedious & time-consuming task of trial-and-error) experienced when using those outdated single-axis 'bubble' or traditional rectangular-measurement, perpendicular profiling and precision 3-Dimentional alignment tasks.

-

Digi-Pas® 2-axis precision VERTICAL digital level simultaneous displays of two-dimensional plane angles, effectively simplifying and resolve the hurdles of taking vertical plane (Z-AXIS) angles 'one axis at a time' iteration (tedious & time consuming task of trial-and-error) experienced when using those outdated single-axis 'bubble' or traditional rectangular-structured FRAME levels to conduct vertical Z-AXIS plane PERPENDICULAR to HORIZONTAL plane (X&Y axis), angle measurement, perpendicular profiling and precision 3-Dimentional alignment tasks.

-

Precision parts/components machining require continuous quality assurance and to control production yield, reduce scraps and thus cost. Setting up of VERTICAL MILLING HEAD against HORIZONTAL work-piece is critical to dimensional accuracy of finished machined parts/components. Digi-Pas® DWL-1900XY enables production team to effectively evaluate each CNC machine VERTICAL Z-axis (Zx & Zy)against HORIZONTAL X&Y axis of work-table surface PERPENDICULARITY (when used in conjunction with DWL1500XY) and providing perpendicularity 3-Dimensional information SIMULTANEOUSLY in real-time on smartphone or tablet.

-

The simultaneous display for dual-axis feature of Digi-Pas® DWL-1900XY master machinist digital level speeding up alignment procedures and reducing training level for new operators to reliably achieve precise perpendicularity results. Operator does not need to meticulously taking readings in both directions over and again as experienced with traditional single-axis FRAME levelers.

-

Digi-Pas® DWL-1900XY is used together with DWL-1500XY to measure the parallelism of the High Precision CNC double-column machine’s spindle shaft relative to the horizontal X–Y table surface, ensuring accurate perpendicularity between the spindle axis and the machining plane.

-

Digi-Pas® DWL-1900XY is used for aligning precision fixtures. Absolute levelling and positional accuracy are required in meeting tight tolerance for highest quality in many manufacturing processes within semiconductor wafer foundries.

-

Digi-Pas® DWL-1900XY dual axis model is used for monitoring a precision wafer manufacturing equipment's performance.

-

Digi-Pas® DWL-1900XY is used in railway maintenance & operation to detect rail tracks deformation and elevation variations. It is a useful tool in aids for rail lines realignment, repair and construction of a new rail line. Accurate rail tracks longitudinal profile levelling and transversal alignment lead to enhanced safety standard for high speed railway operation.